Full-automatic Antiseptic Filling Machine Equipment:

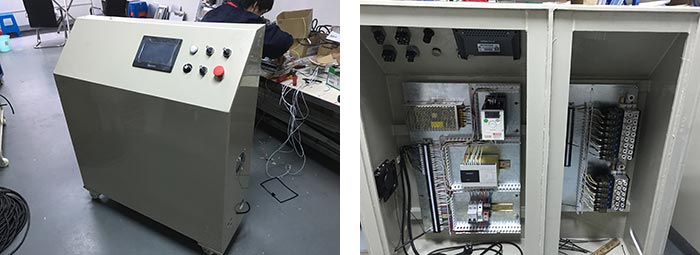

Type: ZGP-6G < With 6 filling heads >

Technical Parameter:1.1 Suitable material: Bleach, acid liquid, 84 disinfectant, gel water, toilet cleaner, especially used in the liquid filling of strongly corrosion liquid and cosmetics which can’t touch the metal.

1.2 Contact liquid parts are use anticorrosive non-metallic material and with diving function.

1.3 This Vertical filler is a high-tech filling equipment integrating on the PLC microcomputer programmable control, and photo electricity transduction pneumatic action.

1.4 The full-automatic antiseptic filling equipment suits for the filling of different sizes of vessel may change the filling sizes within a few minutes. Short filling circle, high production capacity.

1.5 User may choose the filling volume and decide the filling heads per own production capacity.

1.6 The precision time of the pneumatic valve filling may set to 0.01 second, can make the measurement precision control within ±1%, to decrease unnecessary material loss and enhance the economic efficiency.

1.7 Each filling-head’s measurement may be individually adjusted to realize the same filling measurement.

1.8 The full-automatic antiseptic filling machine set such function: having counting program of bottle-feeding, doesn’t fill as there is not bottle or the counting doesn’t attain a predetermined position, can start filling only when the counter records that the bottle number is same as the setting filling number.

1.9 More or less of the filling volume, may initially adjust to the needed filling volume, then micro adjust, can get the ideal filling measurement precision.

Technical Parameter:

|

No. |

Item |

Technical Data |

|

1

|

Capacity |

1000BPH for 350ml bottles |

|

2

|

Filling Range |

50ml-500ml |

|

3

|

Accuracy |

±1% |

|

4

|

Power |

1.1KW |

|

5

|

Voltage |

220V 50HZ |

|

6

|

Weight |

850KG |

|

7

|

Dimension |

2000*1300*2300MM |

Main Configuration:

|

1

|

Touch Screen |

WEINVEIW |

Taiwan |

|

2

|

PLC |

Mitsubishi |

Japan |

|

3

|

Sensor |

OPTEX |

Japan |

|

4

|

Solenoid Valve |

SHAKO |

Taiwan |

|

5

|

Cylinder |

AIRTAC |

Taiwan |

|

6

|

Angle Seat Valve |

BURKERT |

Jointed |

|

7

|

Frequency Converter |

Schneider |

France |

|

8

|

Button |

Schneider |

France |

|

9

|

Magnetic switch

|

AIRTAC |

Taiwan

|

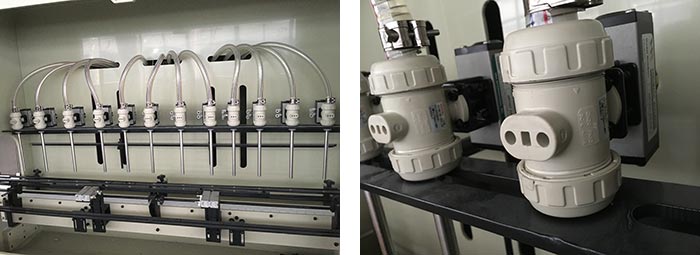

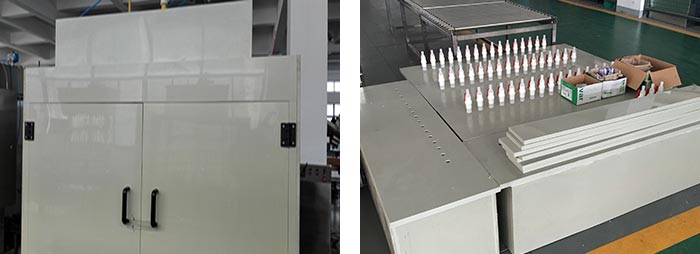

Part of Full-automatic Antiseptic Filling Equipment:

Contact part material : PP < Anticorrosive >

Side part of machine:

Filling Part:

Filling Nozzle Material: Can do SS316, also can do PTFE

Valve Material: PP

Individual Control Box:

Individual Control Box Material: PP

Tank part:

Tank Material: PP

All stainless steel have covered with Teflon ( Black part as photo shows)

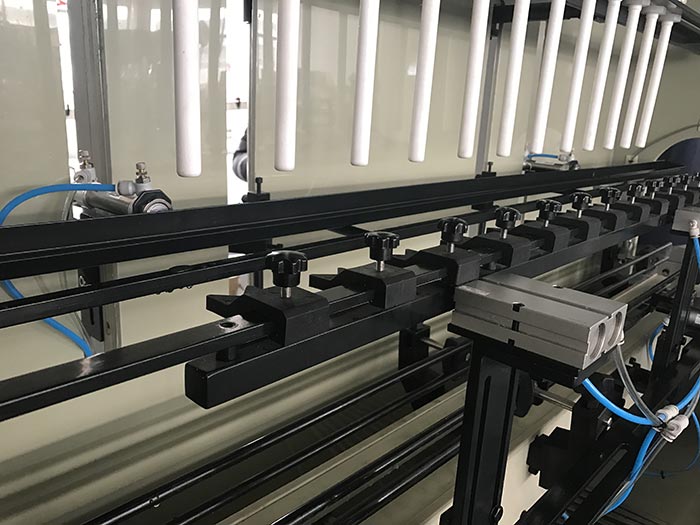

Conveyor detail photos :

Side conveyor material: PP

Spare parts list:

|

Item |

Specification |

Quantity |

|

Joint |

APL-6-01 |

6 pieces |

|

Admission valve |

ASL-6-01 |

6 pieces |

|

Admission valve |

ASL-8-03 |

3 pieces |

|

Screw |

M6,M8,M10 |

|

|

Nut |

M6,M8,M10 |

|

|

Potentiometer |

10KΩ |

1 set |

|

Electromagnetic valve |

2 sets |

|

|

Crank |

1 piece |

|

|

Tools kit |

1 set |

|

|

Tools box |

1 piece |

|

|

Instruction |

1 piece |