Automatic Antiseptic Filling Equipment which is made by King Machine has a reliable quality.King Machine is a beverage machine supplier from China.

1 Brief Introduction of Automatic Antiseptic Filling Equipment:

2 Technical Parameter

| No. | Full-Automatic Antiseptic Filling Machine | Technical Data |

| 1 | Capacity | 1000BPH for 350ml bottles |

| 2 | Filling Range | 50ml-500ml |

| 3 | Accuracy | ±1% |

| 4 | Power | 1.1KW |

| 5 | Voltage | 220V 50HZ |

| 6 | Weight | 850KG |

| 7 | Dimension | 2000*1300*2300MM |

3 Main Configuration to Automatic Antiseptic Filling Equipment

| 1 | Touch Screen | WEINVEIW | Taiwan |

| 2 | PLC | Mitsubishi | Japan |

| 3 | Sensor | OPTEX | Japan |

| 4 | Solenoid Valve | SHAKO | Taiwan |

| 5 | Cylinder | AIRTAC | Taiwan |

| 6 | Angle Seat Valve | BURKERT | Jointed |

| 7 | Frequency Converter | Schneider | France |

| 8 | Button | Schneider | France |

| 10 | Magnetic switch | AIRTAC | Taiwan |

4 Part of Automatic Antiseptic Filling Equipment:

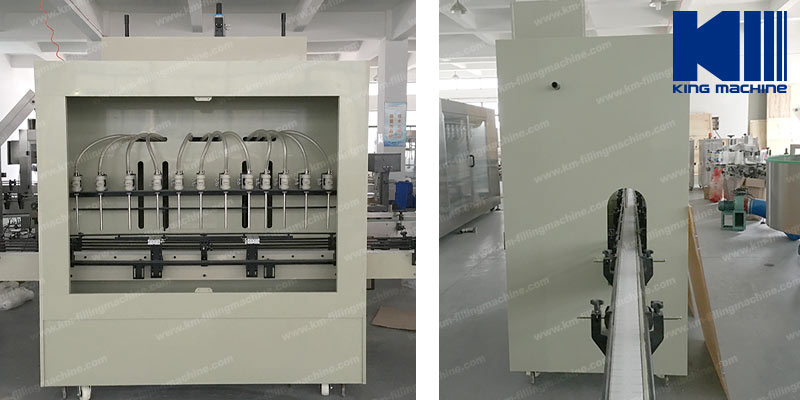

Side part of Automatic Antiseptic Filling Machine:

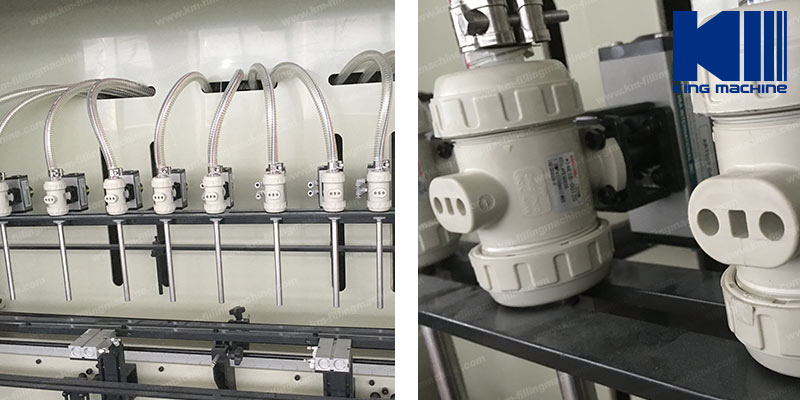

Filling part :

Filling Nozzle Material: Can do SS316, also can do PTFE

Valve Material: PP

Individual Control Box :

Individual Control Box Material: PP

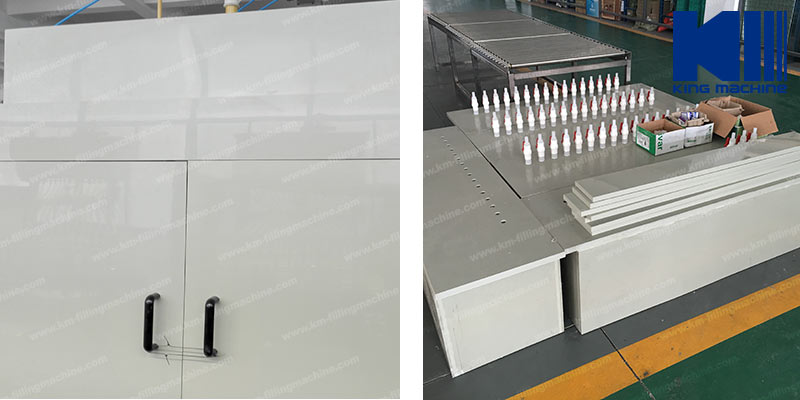

Tank part:

Tank Material: PP

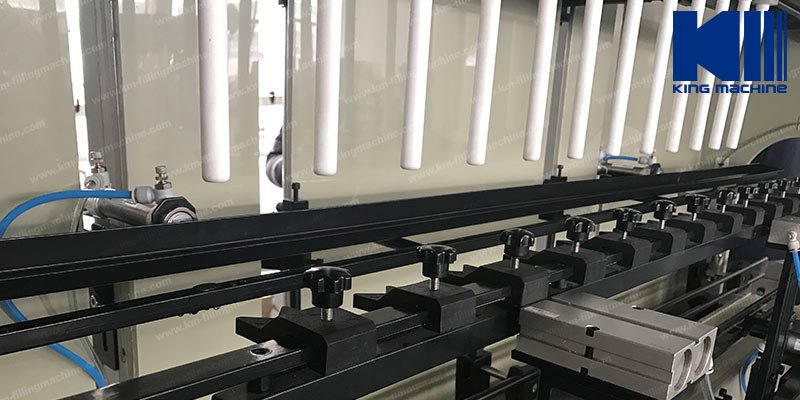

All stainless steel have covered with Teflon ( Black part as photo shows)

Conveyor detail photos :

5 Spare parts list:

| Full-Automatic Antiseptic Filling Machine | Specification | Quantity |

| Joint | APL-6-01 | 6 pieces |

| Admission valve | ASL-6-01 | 6 pieces |

| Admission valve | ASL-8-03 | 3 pieces |

| Screw | M6,M8,M10 | |

| Nut | M6,M8,M10 | |

| Potentiometer | 10KΩ | 1 set |

| Electromagnetic valve | 2 sets | |

| Crank | 1 piece | |

| Tools kit | 1 set | |

| Tools box | 1 piece | |

| Instruction | 1 piece |

6 Video Show: