Edible Oil Filling Production Line Description:

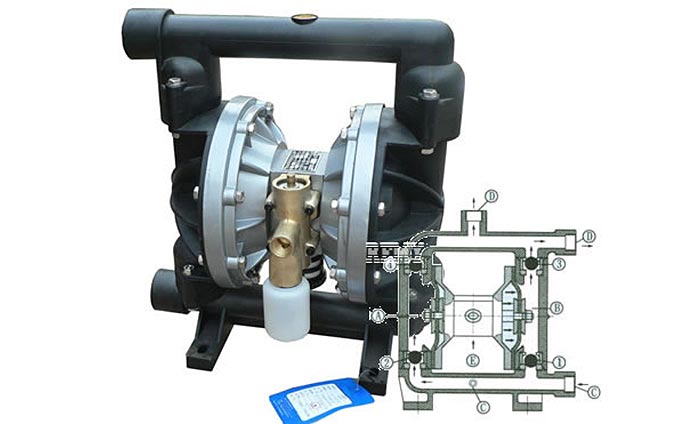

1. Diaphragm pump

Brand: China Nanfang Southern Pump

Flowing:10T/H

Liquid temperature:

Normal temperature type: -15℃~+70℃

Hot water type: +70℃~+110℃

Highest ambient temperature: +40℃

Max.operation pressure :10 bar

Max.inlet pressure is limited by max.operation pressure

Motor Power: 3KW

Running speed: 2900rounds/min

2. Automatic rotate table

This equipments main application in filling line, change direction with automatic enter bottle and collect the bottles. It is special designed for the glass bottle up-loader

Technical parameters:

Speed :6000bottles/hour (adjustable)

Motor brand :JIE brand

Material: All 304 stainless steel construction

Dish Diameter: 1500mm

Power: 0.75Kw

Dimension: 1200*1200*1300mm

3. Edible Oil Filling Machine

The edible oil filling machine is a high-tech product designed and developed by our company. It mat suit for different viscosity of water agent, semi-fluid and paste, it is widely used in the product filling of foodstuff, cosmetics, medicine, grease, daily chemical industry, detergent, pesticide and chemical industry. Using the straight filling way, may be used in the different vessels, needn’t add any parts.

Edible Oil Filling Machine Features:

1. The series machine, its design compact and reasonable, the appearance artistic and scholar.

2. Choosing the international brand of electrical components. The main powered cylinder, chose the Taiwan Airtac double-action cylinder and magnetic switch, the Japanese Mitsubishi PLC computer, photo electricity and Taiwan-manufactured touching screen, ensuring a good quality and lasting steady performance.

3. The Edible Oil Filling Machine has a convenient maintenance, needn’t any tools, may easily dismantle, clean and fix adjustment convenient. The measurement’s adjustment, may at first large range adjust to approaching measurement, then micro adjust.Make not to fill when there is not bottle or lack of bottle, ensuring the accurate measurement.

4. May determine the filling-head number and the cylinder volume per the user’s production demand. The 4-heads,6-head, 8-head and 10-head mat be chosen, the cylinder volume has 25-250ml, 50-500ml, 100-1000ml and 250-2500ml. 100ml-5000ml ,The whole machine has speed-adjustable bottle-conveying tape, high strength stainless steel framework, firm and durable.

5. Considering the different viscosity of user’s material especially set a filling suffocated valve of preventing drop and preventing feathering, as well as a descending filling lift system. In order to make the material-falling aim at the bottle mouth accurately, designed a horizontal bottle-aiming fixture device, ensuring the aim’s correct.

6. Because of the complicated material varieties, the edible oil filling equipment set a weight filling program to fix the parameter, for the thin liquid, may use the atmospheric timing filling way to decrease production cost ad to enhance the production speed. The system needs not add any parts, may decrease the equipment’s repeated investment, and realize the one-machine multi-use.

7. The machine’s filling system used the chuck quick-fixing hygiene joint. The cylinder’s whole body, from to top to the bottom, needn’t any tools, may easily dismantle, clean and fix. Its structure design simple, operation maintenance convenient.

Technological parameters:

|

1

|

Model |

KOF12 |

|

2

|

Speed |

2500-3000bottles/hour based on 1L |

|

3

|

Filling range |

1000ml~5000ml |

|

4

|

Measurement precision |

±0.2% |

|

5

|

Working power |

220VAC |

|

6

|

Air pressure |

6~7㎏/㎝² |

|

7

|

Air consumpation |

1m³/min |

|

8

|

Power rate |

0.8kw |

|

9

|

Other devices power rate |

7.5kw(air compressor) |

|

10

|

Net weight |

1850Kg |

|

Counter size |

3200mm×1200mm×2200mm |

|

No. |

ITEM

|

SUPPLIER |

Brand |

|

1

|

Touch screen |

Taiwan |

Eview |

|

2

|

PLC |

Japan |

Siemens |

|

3

|

Photo sensor for bottles |

Japan |

Panasonic |

|

4

|

solenoid valve |

Taiwan |

SHAKO |

|

5

|

Level button |

Mexico |

JOHNSON CONTROLS |

|

6

|

Piston cylinder |

Taiwan |

AIRTAC |

|

7

|

Servo motor |

France |

Schneider |

|

8

|

angle seat Valve |

Jointed |

BURKERT |

|

9

|

Other divices |

Taiwan |

AIRTAC |

|

10

|

Power button |

Taiwan |

Mean Well |

|

11

|

Button |

France |

Schneider |

|

12

|

frequency converter |

France |

Schneider |

|

13

|

bottle- transport motor |

China |

Huangyan |

|

14

|

Speed reducer |

China |

Jiao xing |

|

15

|

Relay |

Japan |

Omron |

4. Automatic Cap Press Machine

The TYPE FM-160B full-automatic vertical lid presser is a newly-type lid-revolver improved by our company. The machine’s appearance is artistic and scholar, flexible, quick lid-revolving speed, high conformity rate, it may suit for the different bottle shape’s lid-pressing for foodstuff, pharmacy, daily chemical industry, pesticide and cosmetics. The four units of speed-adjustable motors is separately used in lid-feeding, bottle-clamping, conveying and lid-pressing, the machine has a high automation degree, good steadiness, convenient adjustment, changing bottle sizes or lid, needn’t any parts, only need some adjustments (for example, link with the lid-feeder, may automatically feed lids)

5. Cap Eleavator

Material:SS304

Motor Power:0.25KW

Package Dimension:2700mm×700mm×3000mm

Weight:240kg

6. Buffer Conveyor

The buffer conveyor is placed before the packing machine ,so you can save the factory space and to keep the bottles ,and you can have time to change the labels or package film .

Material :SUS304 stainless steel side panel with plastic chain

Width :320mm for 4lines

Height :1080mm (adjustable)

Power:1.1KW

7. Automatic Sleeve Label Shrink Machine

Max Capacity :9000BPH(on the base label length:500ml)

Label size: Diameter 30-125mm

Bottle diameter :Diameter28-125mm

Label sleeve length: 30-250mm

Thickness : 〉0.035mm

Label material: PVC/ PET

Electrical power : 2.5KW (380V 50HZ)

Overall diameter : 2440*890*2200mm

Weight : Approximate 750KG Including the steam thermal shrink machine

8. Code Sprayer

Automatic Code Sprayer

Function

1) Single nozzle can spray two lines of information.

2) Height of characters (1.8mm) (2.5mm) (3.2mm) (3.9mm) (5.8mm).

3) Many languages: Latin, Arabia, Japanese, Chinese and Korean.

4) Production date, future date or best-before date, time, shifts and automatic counting 2 calculators.

5) Bar codes: 2/5 code 39 code.

6) Automatic start and off.

7) Interface operation: 128×32 LCD screen menu key and LED indicator light.

8) Manual keyboard: 240×128 LCD screen WYSIWYG information display and drop down menu.

9) More than 99 pieces of information are in store.

10) Interface of Many languages: More than 20 languages are optional such as English, French, Italian, German, Russian, Japanese, Chinese, Korean.

9. Semi Automatic Carton Filling Table(belt )

It is used for bottle collect and carton fill ,Length 2meter ,width 1200mm .

10. Carton Fold and Sealing Machine

Auto folding for top lid ensures smooth and suitable sealing motions. The entire sealing operation is automatically performed, providing elegant outlook and labor-saving, the machine can be operated together with an automatic packaging line.

11. Automatic PE Film Shrink Wrapping Machine

PE film group packing machine is suitable for wrapping of such products as pop-top,mineral water,bottles,beer,drinks etc without bottom-tray ,working with PE shrink tunnel to pack the goods perfectly ,the whole producing process adopts the Germany advanced technology, and the main parts are imported from international famous companies ,Capability stable and using long-time

Function:

1. It can connect with the filling line directly by conveyor system,All process from bottle feeding ,packing ,sealing ,cutting can works automatically.

2. Frequency control,Secondary bottle transport device.

3. The whole set which are push bottle,heat sealing cutting adopt pneumatic structure.

4. Inductive switch control film length.

5. Touch screen,PLC control system advanced reliability of the equipemtn function.

6. Circular wind machine ,resuare well-proportioned temperature of the shrink furnace.

7. Strong cooling system can reassure finalize the design quickly.

8. Heat-fast Teflon transport net,transport steady,high strength and stand wear and tear.

9. Frequency conversion timing net transportation structure.

10. The height of the conveyer belt can be made according to the user,adustable range±50mm

11. Bottle transport machine can satisfy the direction of the user,it can prolong and shorten

12. Pterygoid stainless iron heating system,durability.

13. Satisfy the bear storage rack device of the short duration for the product,assure consecutive work for the production line.

Technical Parameters:

Outline dimension of the equipment:L5050*W3300*H2100mm.

1. The largest dimension of the wrappage:L600*W400*H350mm.

2. Material of shrink film:PE,PVC.

3. Thickness of shrink film:0.03-0.15mm.

4. The highest temperature of the heat shrink furnace: 160-260。Can adjust freewill.

5. The maximum production per minute:0-12 pakage.

6. Equipment capacity: 20Kw.

7. Actual power consumption:15Kw/hour.

8. Pressure request:220V.

9. Equipment weight:1.2T.

10. Machine reuired air pressure of the compressor:0.6-0.8Mpa.

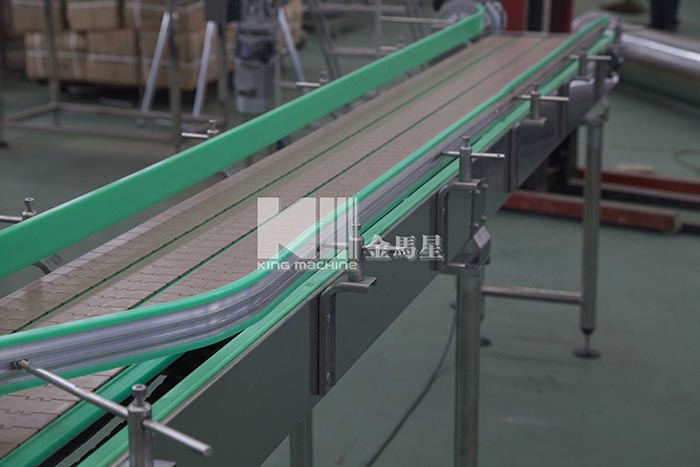

12. Conveyor System

1.Side panel: 304 stainless steel wire-drawing sheet, thickness is 2.5mm.

2.Motor: Hangzhou Jie brand

3.Supporting leg: 304 stainless steel pressing structure

4.Trunking and cover: 304 stainless steel, thickness is 1mm.

5.Chain plate: Domestic high-quality plastic chain plate, polyoxymethylene (POM).

6.Bearing housing: 304 stainless steel cage